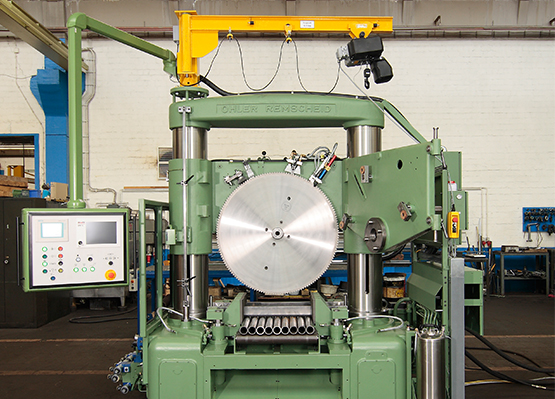

Circular cold sawing machines from OHLER have a long-standing tradition. Their typical design features are proven, and have therefore remained characteristic traits until today. Even with increased demands regarding the materials to be cut, the cutting parameters used and the utilized saw tools, OHLER circular cold sawing machines are able to convince.

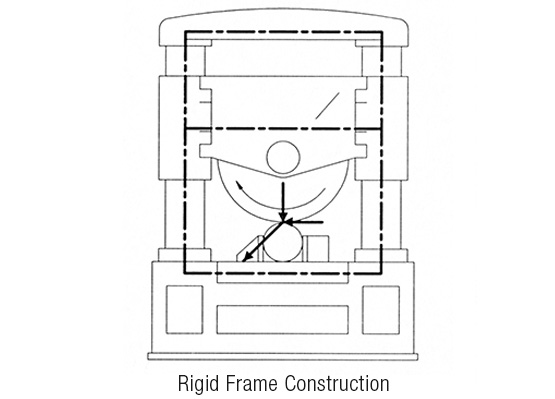

The frame of the machine is comprised of a stable base made of cast iron, two columns with a cross bar and the carriage which runs vertically between the cylindrical column guides. Saw blade and feed cylinder are thereby precisely in the center level of the machine. All cutting forces act against the fixed clamping spindle side, and are dispersed within the closed system.

The heavy machine body made of cast iron also absorbs vibrations, just like the amply dimensioned helical bevel gearbox in combination with a worm gear.

The cutting forces are absorbed by exceptionally large-surfaced carriage guides. During the sawing, they absorb the horizontally acting partial forces of the cutting pressure; the vertical cutting pressure is generated by two synchronized hydraulic cylinders which compensate the weight of the saw carriage. This ensures an extremely long service life of the guides.

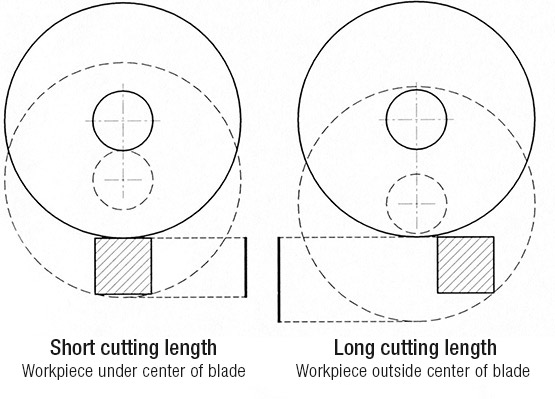

A centric material clamping ensures the shortest possible cutting paths and saw times. The in-feed and discharge clamping of the workpieces in conjunction with robust vertical guidance of the saw carriage produces low-ridges and rectangular sections.

Very high cutting performances can be achieved through the use of LENNARTZ carbide-tipped circular saw blades. Material up to a tensile strength of 1500 N/mm² can be cut.

VDepending on the requirements, the OHLER circular cold saw machine offers the unique option to utilize carbide-tipped circular saw blades and segmental circular saw blades. The machine can provide a high torque even at low cutting speeds through the 6-speed manual transmission and the resulting possible gear ratios. Through the use of a frequency inverter, it is possible to attain all possible cutting speeds between the transmission steps.

| K-630 NIRO | K-630 HSS | K-630 KOMBI | K-630 HM | K-630 S | |

| Power [kW] | 7.5 | 7.5 | 15 | 22.5 | 22.5 |

| Switching transmission | 6 level | 4 step | |||

| Cutting speeds with a saw blade diameter of 630mm [m/min] | 4 / 6 / 9 /

12 / 16 / 23 |

6 / 9 / 13 /

18 / 25 / 34 |

20 / 27 / 39 /

55 / 75 / 104 |

30 / 41 / 59 /

82 / 113 / 156 |

78 / 108 / 158 / 219 |

| Cutting speeds with a saw blade diameter of 630mm with a controlled frequency inverter [m/min] | 3 - 37 | 4 - 54 | 12 - 166 | 18 - 250 | 47 - 350 |

| Saw blade diameter [mm] | 500 - 710 | 500 - 710 | 500 - 710 | 500 - 710 | 500 - 710 |

| max. workpiece dimensions | |||||

| round [mm] | 250 | 250 | 220 | 220 | 220 |

| square [mm] [mm] | 240 | 240 | 210 | 210 | 210 |

| Dimension and weight | |||||

| Length x width x height [mm] | 860 x 1560 x 2140 | 860 x 1560 x 2140 | 860 x 1560 x 2140 | 860 x 1560 x 2140 | 860 x 1560 x 2140 |

| Weight [kg] | 3300 | 3300 | 3500 | 3500 | 3500 |

| K-1000 NIRO | K-1000 HSS | K-1000 KOMBI | K-1000 HM | K-1000 S | |

| Power [kW] | 11 | 15 | 37 | 37 | 37 |

| Switching transmission | 6 level | ||||

| Cutting speeds with a saw blade diameter of 1000mm [m/min] | 4 / 6 / 8 /

11 / 14 / 21 |

6 / 9 / 13 /

16 / 22 / 32 |

20 / 27 / 39 /

51 / 69 / 100 |

25 / 34 / 49 /

63 / 85 / 123 |

60 / 81 / 117 /

151 / 205 / 296 |

| Cutting speeds with a saw blade diameter of 1000mm with a controlled frequency inverter [m/min] | 3 - 34 | 4 - 51 | 12 - 160 | 15 - 196 | 36 - 474 |

| Saw blade diameter [mm] | 800 - 1120 | 800 - 1120 | 800 - 1120 (1150) | 800 - 1150 | 800 - 1120 (1150) |

| max. workpiece dimensions | |||||

| round [mm] | 400 | 400 | 350 | 350 | 350 |

| square [mm] [mm] | 385 | 385 | 330 | 330 | 330 |

| Dimension and weight | |||||

| Length x width x height [mm] | 1260 x 2060 x 2705 | 1260 x 2060 x 2705 | 1260 x 2060 x 2805 | 1260 x 2060 x 2805 | 1260 x 2060 x 2805 |

| Weight [kg] | 6700 | 6700 | 7000 | 7000 | 7000 |

The conversion is performed while maintaining the machine housing and the large-scale column guides, and thus also ensures the decisive advantages of the OHLER cold circular saw machine for the utilization with carbide-tipped tools.

Such a modification essentially consists of:

A tool breakage monitoring can be adapted.

Last but not least, this modification provides a significant price advantage compared to the new purchase of a machine with an absolutely comparable cutting performance.