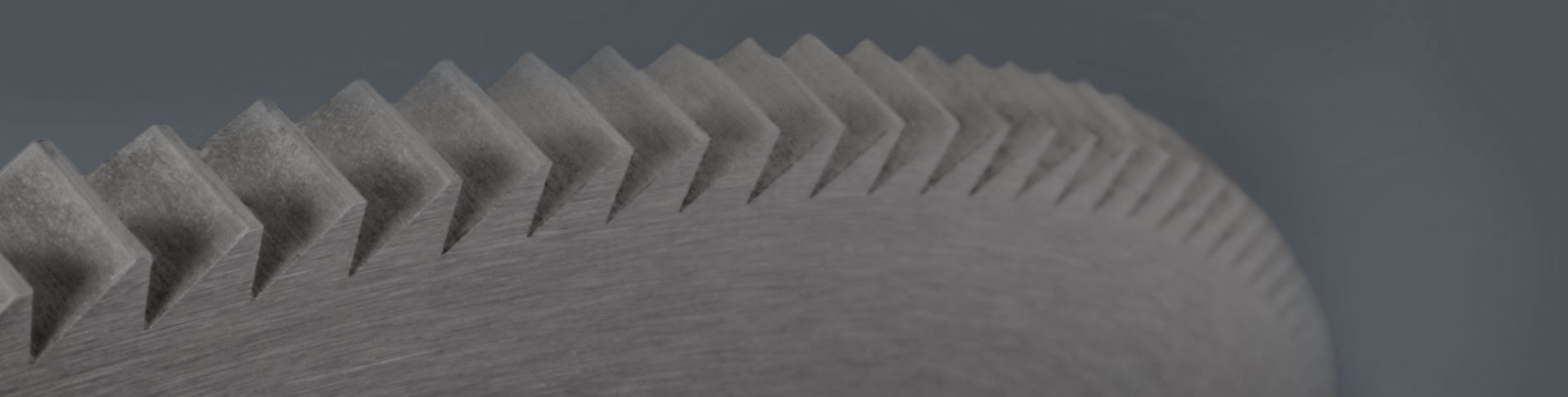

Friction Saw blades range from 12” (300mm) to 84” (2100mm) and are designed to cut cold carbon and alloy steels at surface speeds of 18,000 to 26,000 surface feet a minute (SFM ). The fine tooth pitch is used to generate frictional heat during the cutting of thin wall tubes, conduit, pipe, structural beams, pilings, angles and channels.

Some of the most popular tooth forms available include the V, U, Promo / Parrot tooth, a 60 degree included Pyramid – M style tooth, taper top M style, M style with a specified land and swaged style tooth.

Friction blades are manufactured according to the customers applications utilizing carbon, chrome vanadium, manganese steel grades and special alloys optimized for extended blade life and reduced cracking.

The friction blades are precision machined and fitted with milled tooth forms followed by a uniform through harden and tempered heat treat process. Skilled saw smiths with years of experience hammer, straighten and tensioned the blades for vibration free cutting. The blades are surface ground with controlled side clearance, balanced and accurately sharpened to provide efficient cutting.

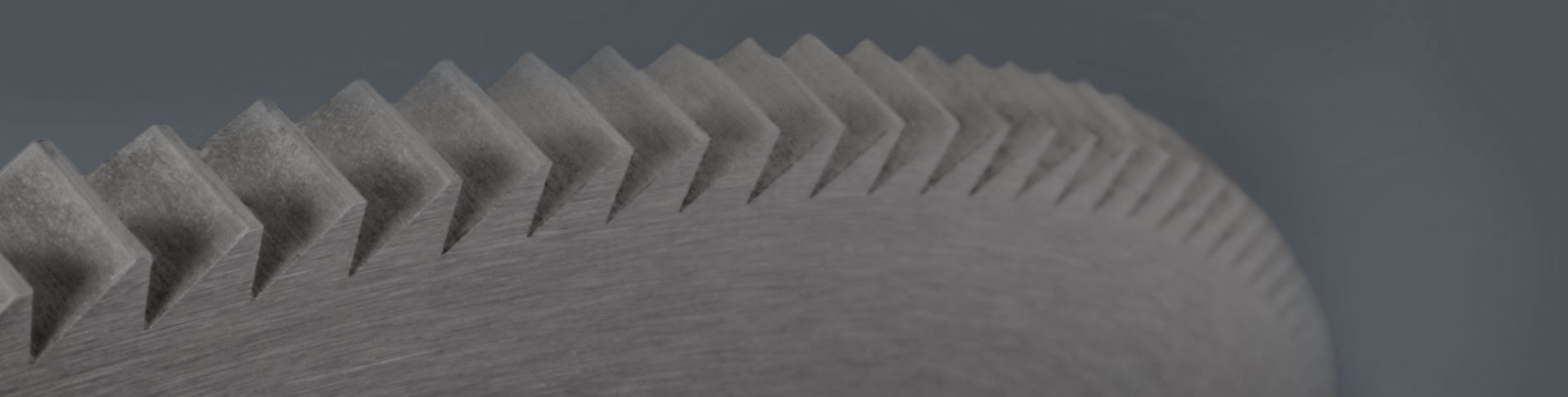

Hot Saw cutting blades for the Steel Cutting Industry are used in stationary or flying cut off applications at mills with continuous casters, hot rolling mills for billets, rails, structural sections, and tube mills with temperatures of the product exceeding 750 degrees C / 1385 degrees F and cutting the materials at rim speeds of 16,000 to 25,000 surface feet a minute ( SFM ).

Heinemann Hot Saws are available from 30” (765mm) to 84” (2100mm) with the standard pyramid open gullet tooth form or the recumbent modified V style as well as customized tooth profiles to suit the customers’ requirements. The hot saw cutting blade requires a copious flow of coolant under high pressure that is directed into the teeth to essentially clear the debris from the tooth gullets and keep it clean and cool with every saw revolution.

The blades are available in a wide selection of carbon steel grades, manganese steel grades and special alloy component steels depending on the applications.

Typically, the hot saw blade is surface ground flat with parallel sides or taper ground to a hub for additional side clearance in cutting large profiles. Skilled saw smiths trained to straighten and tension the hot saw blades for each unique cutting application will also demonstrate the quality that is built into every new blade by providing the cutting performance that can be measured and effectively reduce the cost of operations.

The hot saw is provided with a normalized or tempered body but often can be supplemented with a flame hardened tooth. The teeth are flame hardened by passing the edge through a oxyacetylene flame at a controlled speed and quenched to achieve a harden cutting edge which gives considerable increased blade life between re sharpening.

Heinemann Saw Co. offers technical support to achieve the correct blade and specifications for your sawing applications along with a comprehensive repair and reconditioning service for all Friction and Hot Saw blades.

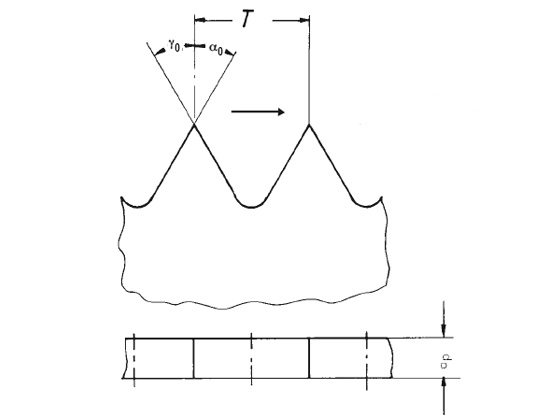

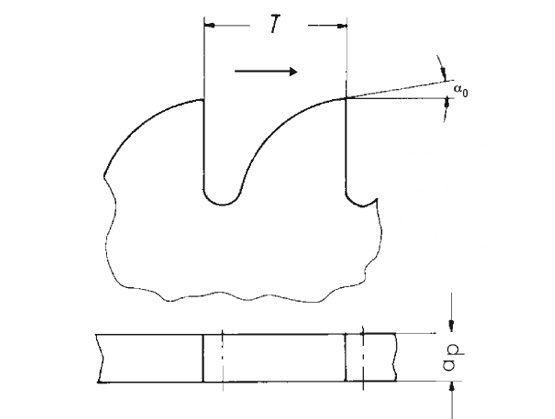

Pendulum saw tooth

γ0/α0 = 30° suitable for the hot and cold cutting of pipes, profiles, beams and solid material

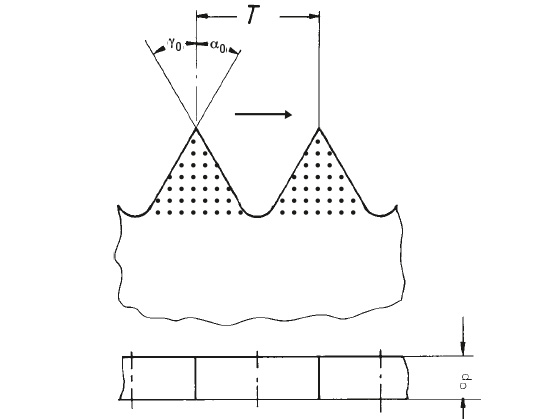

Special version with

tooth-tip hardening

Parrot tooth

γ0 = 0° α0 = 8° suitable for the cold cutting of pipes, profiles and beams

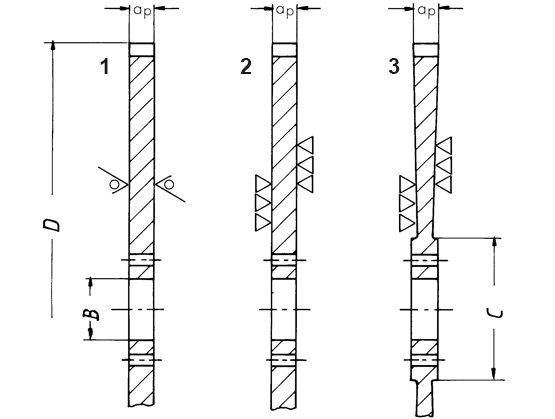

D = saw blade diameter (mm)

ap = cutting width (mm)

B = medium bore diameter (mm)

C = flange diameter (mm)

Version 1: Rolling black sides

Version 2: Side surfaces ground even

Version 3: Side surfaces ground radial conical